Phone: 262-326-0100 eMail: sales@aq-mfg.com

16605 West Victor Rd, New Berlin, WI 53151

Tooling Capabilities

We do our own in house CAD design and to create our own holding fixtures for your parts, using either your part blue prints or model, we are able to have complete control over your finished part. This allows us to provide higher quality machining with shorter lead times with less cost.

Creating our own in-house tooling allows us faster startup times, since we don't need to wait for tooling production. This also allows us to do immediate modification when necessary. This is especially useful in product development and product trouble shooting.

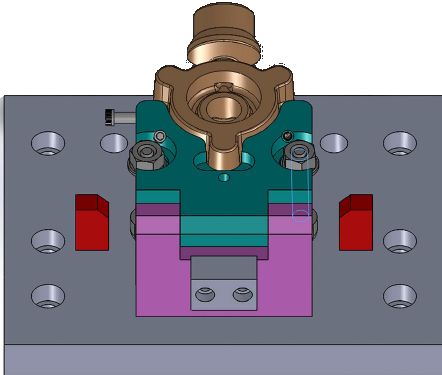

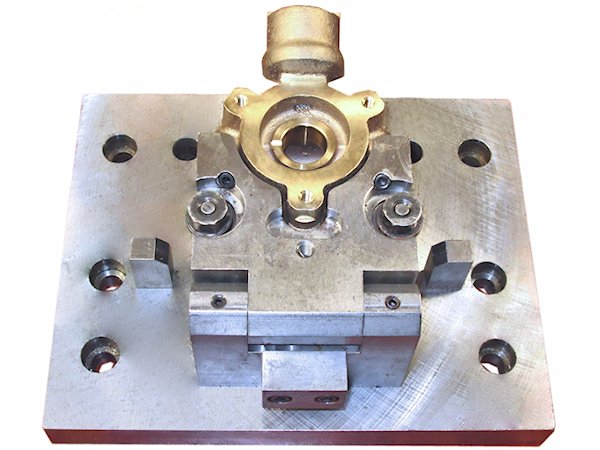

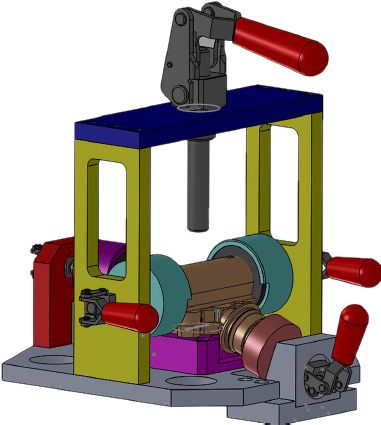

Below is an example of our tooling process:

A CAD design was created for Operation 1. This provided the fixture that allowed the CNC Machine to hold the casting for the first milling operation. This operation included milling the outer surface, drilling and tapping the screw hole locations, boring and facing the internal hole.

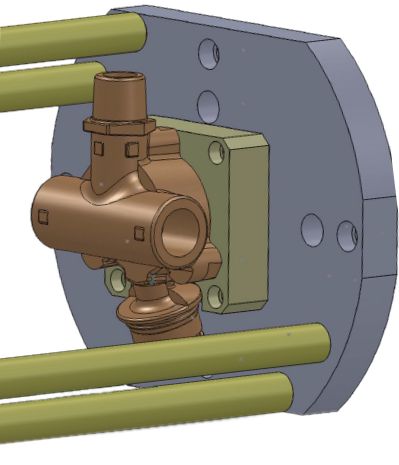

A Second CAD design was created for Operation 2. This provided a fixture that allowed the CNC Machine to hold the casting after Option 1 was completed. This secondary mill operation held the casting to allow the top male NPT thread and the side threaded ports to be machined in one operation.

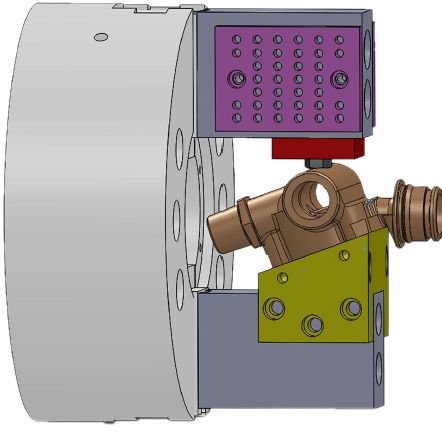

The Third Operation CAD design was created to provide a fixture that allowed the CNC lathe to machine the complex 20 degree profile.

The final CAD design for this project was to create a custom pressure test fixture to ensure the valve is airtight. Once loaded and pressurized the whole unit was placed underwater to determine if any air was escaping.

The Result: The finished product!

We are committed to Quality and Customer Satisfaction!

Home | Machining Capabilities | Tooling Capabilities | Quality Control | NQR | Contact Us